Kento Yamagishi Lecturer

Hongo Campus

Nano Physics & Device Technology

Biomedical engineering/Biomaterial science and engineering

Electronic materials/Electric materials

Electron device/Electronic equipment

Thin film/Surface and interfacial physical properties

高分子化学

Ultrathin film electronics for healthcare and medical applications

We aim to develop electronically functionalized 'ultra-thin film electronics' by implementing and printing electrodes, wiring, antennas, etc., on polymeric ultra-thin films with a thickness ranging from several hundred nanometers to a few micrometers. This technology is intended for applications in the healthcare, medical, and sports fields, with the goal of creating devices that can be adhered to soft biological tissues such as the skin and organs, functioning like a sticker.

Research field 1

Electronic nano-bandage for sports applications

Conventional wearable devices, when placed on sensitive and friction-prone areas like the palm or sole, can disrupt movement and pose a significant challenge in measuring muscle activity (surface electromyography: sEMG). To tackle this issue, we've developed a nanosheet (with a film thickness of several hundred nanometers) crafted from a conductive polymer, serving as a bio-electrode directly affixed to the skin. We've dubbed it the "electronic nano-bandage." The electronic nano-bandage adheres seamlessly to the skin's surface solely through van der Waals force, eliminating the need for adhesives due to its ultra-thin and flexible nature. It enables surface electromyography measurement with a signal-to-noise ratio comparable to commercially available medical gel electrodes. Additionally, we've introduced a groundbreaking design for a wearable stretchable wire, ensuring a stable electrical connection without impeding the wearer's natural movements, even during vigorous physical activity. By combining this wearable stretchable wire with the electronic nano-bandage, we've achieved the world's first successful measurement of sEMG on the palm during baseball pitching. This device shows promise not only for athletes but also for professionals in fields like music and craftsmanship that demand dexterity. Moreover, we anticipate its application as electrodes in healthcare devices for infants, the elderly, and individuals with disabilities.

Research field 2

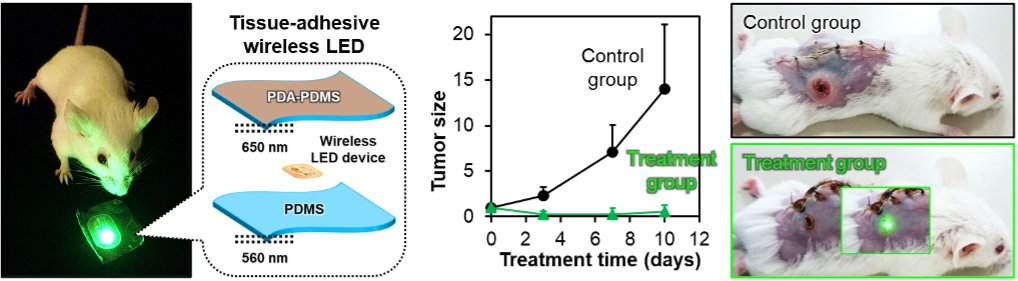

Implantable wireless optoelectronics for cancer therapy

In photodynamic therapy (PDT), which involves accumulating a photosensitizer in the lesion area and using light to induce reactive oxygen species that destroy cancer cells, precise alignment of the tumor and light source is crucial for effective treatment. Therefore, there has been a need for the development of a light-emitting device that can be stably fixed within the body on organs and tissues for an extended period. To address this, a highly tissue-adhesive polymer nanosheet was created by modifying its surface with a bio-adhesive polydopamine that mimics the adhesive proteins secreted by mussels. By combining this nanosheet with a wireless-powered LED chip, a light-emitting device that can be adhered to the surface of internal tissues like a sticker was developed. Furthermore, in collaboration with medical doctors, the fully implantable PDT system was successfully demonstrated using cancer model mice. This device, which does not require sutures during transplantation, can be applied to tissues that involve critical blood vessels or nerves, as well as structurally fragile tissues. Additionally, due to its ability to operate with very weak light compared to conventional methods, concerns about side effects related to thermal damage are minimized. Therefore, this device holds the potential to expand the application of PDT to deeply located organ cancers such as liver and pancreatic cancers.

Research field 3

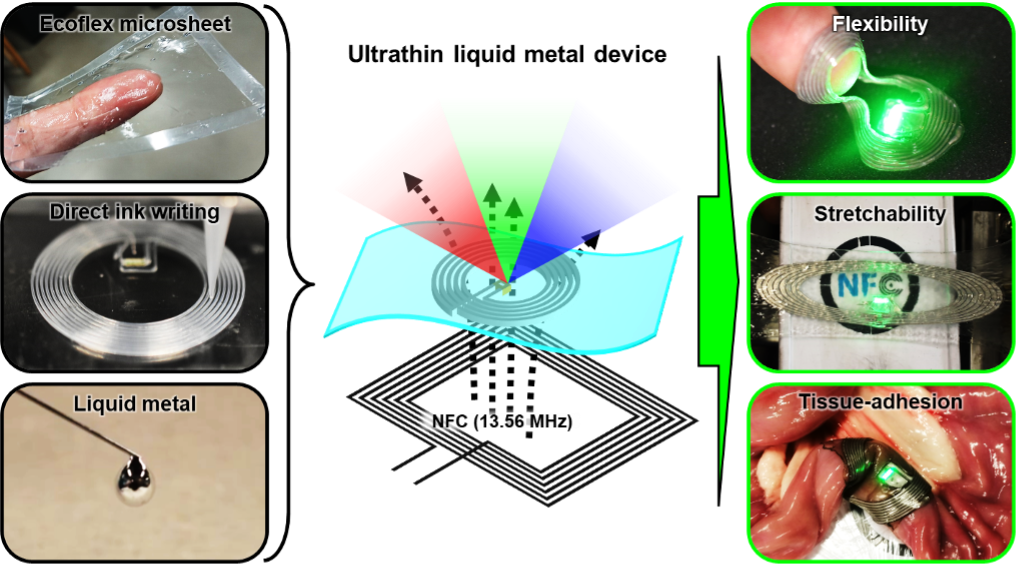

Ultrathin liquid metal devices mechanically conforming to biological tissues

Gallium-based liquid metals, such as EGaIn or Galinstan, are widely utilized in the development of stretchable electronic devices due to their liquid state at room temperature, low toxicity, and high electrical conductivity. There are two main methods for fabricating liquid metal devices: 1) directly printing and encapsulating liquid metal onto a substrate, and 2) forming microchannels, for example, through photolithography and subsequently injecting liquid metal. However, both methods face challenges as the substrate becomes thicker than 100 microns, impacting the overall flexibility and adhesiveness of the device. To address this, we have established a technique using direct ink writing (DIW) 3D printing to directly form liquid metal circuits on elastomeric ultrathin films with a thickness of a few microns. As a specific example, we manufactured a wireless light-emitting device by incorporating an LED into microchannels printed in the shape of an antenna coil and injecting liquid metal. This device demonstrated excellent flexibility, stretchability, and durability against deformations such as bending, stretching, and twisting. Furthermore, stable adhesion to moving biological tissues was achieved by modifying the thin film surface with polydopamine. This technology is expected to offer new possibilities as a design and manufacturing guide for flexible and stretchable electronic devices that mechanically conform to humans, animals, and soft robots.